Connect with us +33 1 41 19 29 70-

Printing supplies and equipment shop Digital Direct to Garment printer Platen for Brother Printer Shoe platen Brother

Composition of the Kit :

Three (3) Shoe Platen Inserts

Three (3) Shoe Platen Inserts

Both Shoe Platen Kits come with a three different size Shoe Platen Inserts. This allows for most size and styles of footwear to be printed on. The Medium and Large Platen Inserts also allow for undermount blocks that can be used to secure the footwear from the bottom should it be desired.

All the Shoe Platen Inserts are made out of durable and flat polycarbonate material.

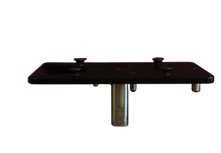

Mounting Kit (Included with the Complete Kit Only)

Mounting Kit (Included with the Complete Kit Only)

The Mounting Kit, also used on the Touchdown Platen, is required in order to mount the Shoe Platen Inserts on to the GT printer. The Mounting Kit uses the same pin setup as the standard GT Adult Platen that comes with the different GT Printers.

This allows the Shoe Platen Kit to mount on all the different GT printers.

For those GT users that already have a Touchdown Platen, only the Shoe Platen Basic Kit is needed.

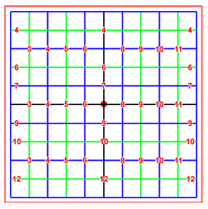

Alignment Jig

Alignment Jig

STEP BY STEP INSTRUCTIONS

Below you will find detailed instructions, from start-to-finish, on using the Shoe Platen Kit on a GT Printer.

- Attach the appropriate size Shoe Platen insert (based on the shoes being printed) to the Mounting Plate. Tighten the screws using your finger or M4 allen key (not included).

- Cover the Shoe Platen insert with double-sided tape (or double-sided platen tape). Make sure there is a hole in the center of the Shoe Platen Insert for the Alignment Jig to be inserted.

- Mask off the areas of the shoe that you do not want ink printed on to using standard masking tape or medical tape.

- Load the shoes on to each side of the Shoe Platen insert. Make sure the sides of the shoe are as flat as possible.

- Insert the Alignment Jig in the square cut-out on the Shoe Platen insert.

- Align the artwork in your graphic software program to match up with the Alignment Jig.

- Print the artwork to the GT printer. It is recommended to print in Unidirectional print mode.

- Set the platen height to the proper level based on the shoe that is being printed and press the Platen Feed button on the control panel to test it.

- Press the Print button on the GT printer.

- Carefully remove the printed shoes from the Shoe Platen Insert.

- Cure the printed shoes using a heat gun or conveyor dryer / box.

Additional product information

We also recommend

Browse this category: Platen for Brother Printer